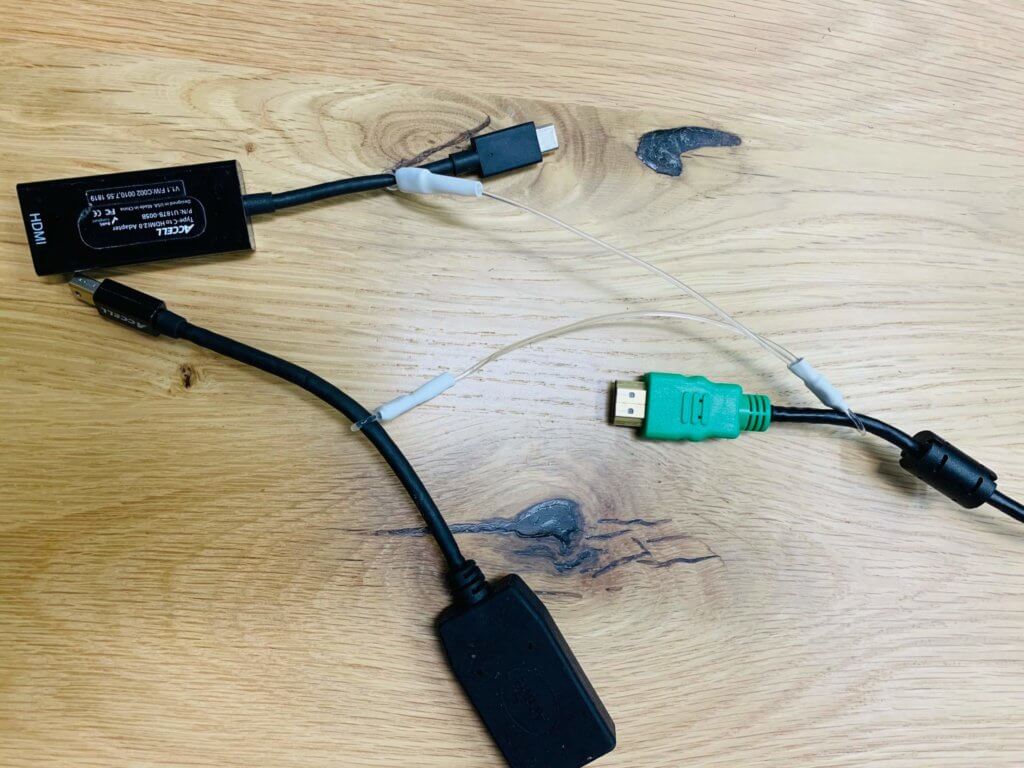

What does it look like to innovate and have a relentless focus on meeting customer needs? One great example was when a large global multi-national customer reached out to our customer success team with a question. They currently used another company’s metal wire cable tether for securing HDMI cables, preventing theft of USB-C dongles, and keeping Apple adapters from being stolen, but were looking for a new kind of cable tether that would not conduct electricity. In addition, they also wanted an innovative product that would have a high weight breaking point and must have a professional look and feel.

The problem driving their custom design request is one that is common for many workplaces. Our customer was concerned that their employees could accidentally shock themselves if a metal cable tether was inadvertently inserted into an electric outlet or other electronic device and thus create a hazardous work environment for employees and visitors. At the same time, their workplace with hundreds of offices, labs, and corporate classrooms around the world were ideal for installing TetherTies to secure their computer adapters and peripherals. So what could we do?

As a company dedicated to innovative products for cable tethering, TetherTies’ engineering team set to work. With a track record of innovating, TetherTies made the perfect partner to custom create a solution to meet our customer’s requirements. Past innovations from TetherTies include our patent pending pre-assembled cable tethers, extendable coiled cable tethers, and multi-adapter cable tethers (for tethering multiple adapters on one cable tether).

As part of the R&D effort, we worked with more than 8 different raw material suppliers to examine potential non-metal materials that would offer the strength, non-metal properties, and feel/fit worthy to be used in both their global headquarters, their labs, engineering facilities, and offices all over the world. We created dozens of prototypes and samples, using a variety of materials, ranging from durable fabrics to coated wire to non-metal materials.

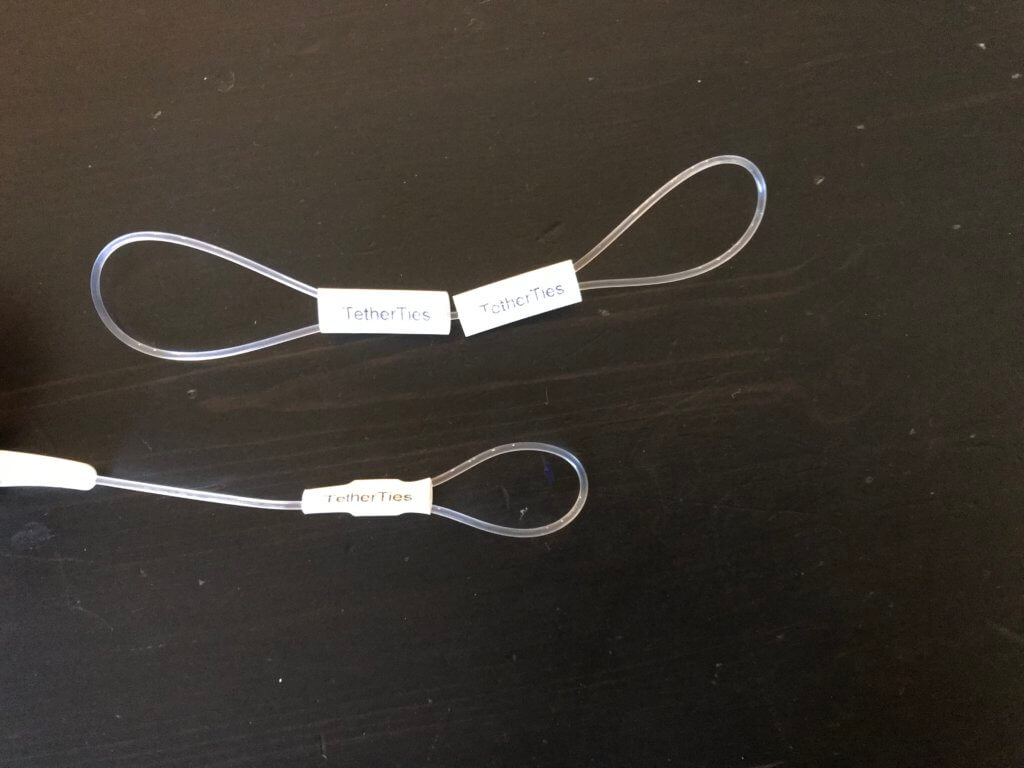

Ultimately, we sent our customer a set of samples that represented our best concepts within 7 days of our initial conversation. Following our customer’s input and feedback we landed on one model that was the perfect design and material. That product is our newest addition to the TetherTies product lineup. Our new non-metal TetherTies product does not conduct electricity and is strong – it features one of the highest breaking points available in any product. With a finished professional look, it was the perfect solution for our global Fortune 500 customer. In fact, they liked our standard pre-assembled model (which secures one adapter) so much that they also asked us to create a new non-metal multi-adapter (which secures two adapters).

Our customer has now specified the non-metal TetherTies as the standard for all new AV installations, and all AV renovations and retrofits. We’ve worked with a number of VAR‘s, US and international re-sellers and installers to price, quote, and deliver this brand new product to our customer’s locations all over the world.

TetherTies prides itself on its unparalleled ability to meet customer needs, work with distributors, and ensure 100% customer satisfaction. So what’s your biggest challenge related to cable tethers? Give us a call to see what we if we can help!

Interested in how you can order our new non-metal TetherTies cable tethers? Email [email protected] and we can get your order going today! The standard pre-assembled non-metal TetherTies are 12 inches in length (11-inches installed length) with a product number of TetherTies MFSF-12PA. The non-metal multi-adapters are 16 inches in length (8 inches installed length) with a product number of TetherTies MFSF-16-MA2. They are also available in custom lengths.